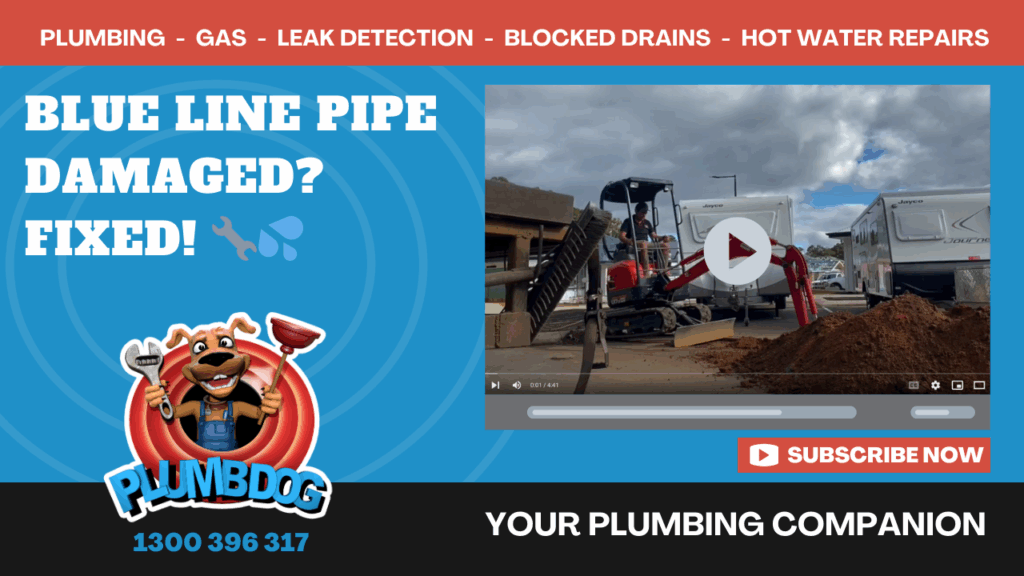

Darius was out in the trenches replacing a water service line at a client’s development site when a surprising discovery came to light.

What should have been a straightforward replacement turned into a detective job:

•The Blue Line poly pipe (usually one of the most durable options) showed scoring along the entire run

•The damage was unusual enough to warrant a closer look

•Out came the inspection camera to assess just how bad things were

💬 “I’ve installed Blue Line poly hundreds of times – but seeing scoring like this is a first for me.”

🔎 Step 1: Investigation

•Dug down to expose the scored sections

•Used an inspection camera to trace the full length of the damage

•Confirmed the pipe couldn’t be trusted long-term

🛠️ Step 2: Repair & Replacement

•Removed the damaged sections

•Installed fresh, undamaged Blue Line poly

•Carefully backfilled with clean bedding material to protect the new pipe from future wear

✅ Step 3: Testing & Wrap-Up

•Pressure-tested the new installation to confirm reliability

•Left the site tidy and ready for the client’s development to move forward

•Another trench job completed with care, precision, and no shortcuts

______________________

📞 Got a water service issue or suspect a hidden pipe problem?

Call the dogs that sniff it out and sort it right the first time.

👉 Call 1300 328 021 or book online at 🌐 www.plumbdog.com.au

🐾 Plumbdog — real plumbers, real trenches, and real solutions across Perth.